Butterfly Valves

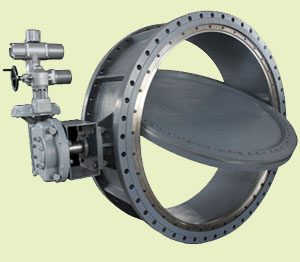

Triple Offset Butterfly Valve – Suprax® Basic Parameters : Triple Offset Butterfly Valves SUPRAX® size range : 3” ~ 200” (DN80mm ~ DN 5000mm) (Note : including all the listed pressure class). Bigger size is doable but should be studied case by case. Pressure class : Class150, Class300, Class600, Class 900, Class1500 – NF EN 1759-1 PN10, PN16, PN25, PN40, PN63, PN100, PN 160, PN 250 – EN 1092-1 Vacuum : 0.05 bars (abs.) / 37.5 Torr (abs.) Connection type : wafer, lug, double flanged, butt-welded Working temperature : -196˚C ~ +750˚C (-321°F ~ +1202°F). Higher temperature is doable but should be studied case by case. Drive type : worm gear, pneumatic, electric and hydraulic. Applicable media : applicable for the pressures ranges from vacuum to high pressure, cryogenic to ultra-high temperature . Double offset Butterfly valve –High performanceButterfly Valves

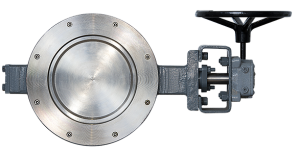

Size Range : BUV21

Basic Type : Class150 2” ~ 48” (50mm ~ 1200mm)

Class 300 2” ~ 24” (50mm ~ 600mm)

Connection Type : wafer, lug

Working Temperature :

-60 ˚C ~ 230 ˚C

Drive Type : manual, worm gear, pneumatic, electric

Applicable Medium : corrosive chemical media, water, gas, acid, alkali, steam, pharmaceutical.

For other fluids, please contact us.

Double offset Butterfly valve –High performance

Butterfly Valves Center Type – BUV 1

Standards & Specifications “Concentric Butterfly Valves” Design standard: API 609/EN593 Connection flange :ISO 7005-2 PN10/16; EN 1092-2 PN10/16; GOST PN10/16; ASME B16.5 CLASS 150; JIS 10K(DN40~DN300); AS/NZS 4087 PN16; Top flange : ISO 5211 Face to face : API 609A /EN558 13 & 20 serial Test standard : API 598 /EN12266-1 Working pressure : PN10/16 (DN40-DN3000 1.5” ~ 120”) PN25 (DN40-DN600 1.5” ~ 24”) Size : BUV12 WAFER (DN40 ~ DN1200 1.5” ~ 48”) BUV12 LUG (DN40 ~ DN900 1.5” ~ 36”) BUV12 U-TYPE FLANGE (DN40 ~ DN3000 1.5” ~ 120”) BUV13 FULLY LINED (DN40 ~ DN1200 1.5” ~ 48”) Testing pressure : (water) Ps (MPa) Shell test : 1.5 times rated pressure Seal test : 1.1 times rated pressure Working temperature : -15°C ~ +130°C Actuator : manual, electric, pneumatic “Center type Butterfly Valves” Products are suitable for fresh water, sea water, sewage, treatment systems, and can also be used in acid, alkali and salty corrosion medias. The valve has passed the ACS, NSF and low lead certification. It can be used in the field of drinking water and food. The valve has passed API 609 certification; it can be applied to petroleum, natural gas and other industrial pipeline transportation systems.Butterfly Valves Center Type – BUV 1

Butterfly valve Center Type – BUV 1

Features BUV12 “Center type / Concentric Butterfly Valves” The disc and shaft are connected without pin to reduce the leak point and achieve on-site replacement. It also can achieve optimal fit and open torque transmission by using O-ring sealing on the shaft. Ball-type sealing is adopted by the connection of Disc and Seat ensuring better connection of Disc and Seat, better sealing capacity and low torque. The semi-shaft design of the Disc efficiently lowers the pressure loss of the valve. The seat has no skeleton. It adopts a bar design and uses thick rubber, which improve the rebound resilience, alowing lower torque, and the interference sealing ensures better sealing results. The seat can be designed by multiple rubber materials to adopt different working condition. The bushing between the shaft and body minimizes the friction and lower the torque value, increasing the valve lifetime. The structure of this concentric butterfly valve is simple and therefore easy to use. Features BUV13 “Full lined Butterfly Valves” Concentric Butterfly Valve The valve is rubber lined by vulcanization injected directly on the body to ensure permanent adhesion. The use of the adhesive layer will enhance the reliability of the butterfly valve. Precision encapsulation and molding process can ensure the lining sealing of the disc and integral flange gasket sealing. With polishing and precision machining on the sealing surface of the disc, the valve is completely sealed, it lowers the operating torque, extends the service life and reach bubble-tight grade sealing. Streamlined design also minimizes pressure loss.Butterfly valve Center Type – BUV 1

Center Type Butterfly Valves

Center type Butterfly Valves BUV12 U – Flange TypeCenter Type Butterfly Valves

Butterfly Valves – BUV13 Fully Lined

Concentric Butterfly Valves – BUV12 Lug Type Center type Butterfly Valves – BUV12 WaferButterfly Valves – BUV13 Fully Lined

Our Clients